Feb 5, 2025 2:09:05 PM

The potential applications of nanoemulsions are vast and varied. In..

Deagglomeration is the process of separating particles that are clustered or clumped together. These particles are dispersed to their primary particle size. Due to material properties, clumping may result which can cause many issues and will require separation.

EXPLORE:

Often times when the material is dispersed it tends to clump together, better known as an agglomerate. These agglomerations can cause many issues in a variety of industries whether that be for coatings or API suspensions. Fibrous and layered materials also need to be separated to truly utilize their superior properties.

The Microfluidizer® processor efficiently uses constant high pressure with reproducible high shear forces to break up agglomerates, to di-fibrillate cellulose nanofibers, exfoliate graphite, where they can be well dispersed and suspended. Microfluidizer® technology has proven to achieve the finely dispersed product.

Microfluidizer® processors are designed to be simple to use, clean and maintain which can be costly and timely. Select Microfluidics equipment provides the option of conforming to cGMP requirements.

Let us use our collective years of application development and machine engineering experience to help drive your product to market as quickly as possible.

Whether your application requires deagglomeration, dispersion, delamination, exfoliation or defibrillation, Microfluidizer® processors provide an efficient solution for it.

Microfluidizer® processors offer an effective solution for applications involving deagglomeration, dispersion, delamination, exfoliation, or defibrillation. Let our team of experts guide you through your options.

Microfluidizer® technology has been extensively used to process both of the 2D and 3D allotropes of carbon and other types nanomaterials.

Two-dimensional (2D) topological materials are currently attracting rapid growing research interests due to their unique properties. The new “wonder” material, graphene, is the mostly studied and opened up huge application potentials. Microfluidizer® technology has been successfully used to produce few layer graphene (FLG) through liquid exfoliation of graphite.

In a recent article published by Cambridge Graphene Center, the uniform high shear generated by the Microfluidizer® processor achieved 100% exfoliation yield with much higher concentrations. The produced FLG was subsequently formulated as highly conductive printable inks. The entire process was water-based without using harsh chemicals which makes it more environmental friendly.

SEM images of blade coated ink formulations comprising (a) starting graphite, (b) after 1 cycle, (c) after 5 cycles, and (d) after 100 cycles. (Source: P.G. Karagiannidis, et. al. Microfluidization of graphite and formulation of graphene-based conductive inks, ACS Nano 2017, 11, 2742-2755 DOI: 10.1021/ acsnano.6b07735

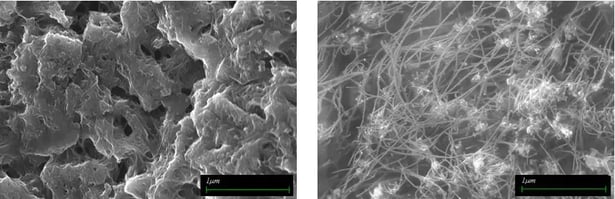

The example of processing 3D carbon nanomaterials is de-agglomeration and dispersion of carbon nanotubes (CNTs). Many studies have been performed using Microfluidizer® homogenizing processor for dispersing either single-walled nanotubes (SWNTs) or multi-walled nanotubes (MWNTs). Our processor can successfully disperse and create stable suspensions of SWNTs and/or MWNTs in various liquid media including polymer resins, organic solvents or simply water. The nanotubes are largely de-agglomerated and dispersed uniformly — in a single pass. During additional passes, length reduction can be controlled based on processing conditions. The dispersion can enhance electrical conductivity as well.

Microfluidizer® technology has been widely studied for the de-fibrillation of cellulose. The results prove that wood cellulose and non-wood fiber samples can be successfully de-fibrillated under several processing conditions. In a recent published study, cellulose nanofibrils (CNFs) were prepared by using a Microfluidizer® processor to disintegrate aqueous pulp dispersion. The produced CNFs were then mixed with nanoclay disperions to obtain composite dispersions. The steady-shear and viscoelastic properties were evaluated and found to be affected by CNF content and interactions between CNFs and clay particles.

Read more about this story.

Microfluidizer® technology is also very efficient for deagglomeration of metal oxides and inks. In a case study, our engineering team used a Microfluidizer® processor to deagglomerate high crystalline cerium dioxide nanoparticles and reduce the particle size. The high shear of our fluid processor significantly reduced the particle size in just a single pass.

Recommended downloads for manufacturers working in the pharmaceutical industry.