How our Microfluidizer® Processors Work

Product enters the system via the inlet reservoir and is pulled into a constant pressure pumping system which pushes the material through a fixed geometry Interaction Chamber™ at up to 30,000psi (2068 bar) where it experiences consistent, high shear rates and impact forces. All material receives the same treatment to achieve consistent, reliable results. After passing through the Interaction Chamber™, the product is effectively temperature-controlled and collected.

The combination of the constant pressure pumping system and exclusive fixed-geometry Interaction Chamber™ is what makes our Microfluidizer® Technology superior and enables our customers to achieve unparalleled success.

A High-pressure Processor Delivering the Highest Shear Rates

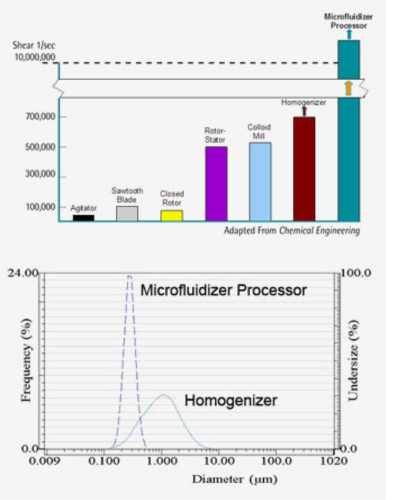

As shown in the shear rate and particle size distribution charts here from Chemical Engineering, Microfluidizer® processors consistently generate significantly higher shear rates than other methods and more uniform particle size reduction.

By precisely controlling the level of shear applied, customers are able to process shear-sensitive materials and high-pressure applications. More efficient reduction of particles to the nano level allows customers to use less energy to achieve particle size results that are, on average, half the size of even the most effective homogenizer outputs.

Uniform Particle Size Distribution

Creating tiny particles is one step. A crucial second factor, often overlooked by manufacturers of other particle size reduction equipment, is generating a uniform particle size distribution in the process.

This is where Microfluidizer® technology has proven its value in thousands of customer applications over the years: producing the most narrow particle size distribution results possible. Naturally, this yields greater stability, longer shelf life, more efficient use of raw materials, and significant potential savings in the filter area.

Microfluidizer® Processors and High-Pressure Valve Homogenizers: No Comparison

Because they are used to process similar applications — albeit with dramatically different results — Microfluidizer® processors are often associated with conventional homogenizers. In reality, the Microfluidizer® technology platform (highlighted by the fixed-geometry Interaction Chamber™) generates a uniform shear field for particle size reduction and robust cell disruption, with repeatable and scalable results, that is not possible with even the most effective homogenizers.

.webp)

GET IN TOUCH

Proven Knowledge and Solutions

Our experts are happy to provide further information about our equipment and how you can benefit form our unique Interaction Chamber™ technology. For precise, reliable results that can be scaled up, contact the Microfluidics team.

Advantages of Microfluidizer® Technology vs. conventional homogenizers:

Smaller Particle Sizes

Microfluidizer® processors generate unrivaled shear that is orders of magnitude higher than homogenizers.

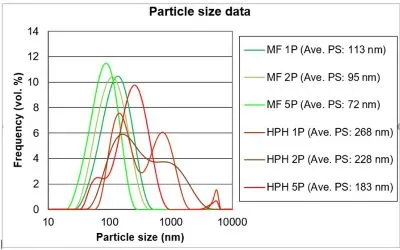

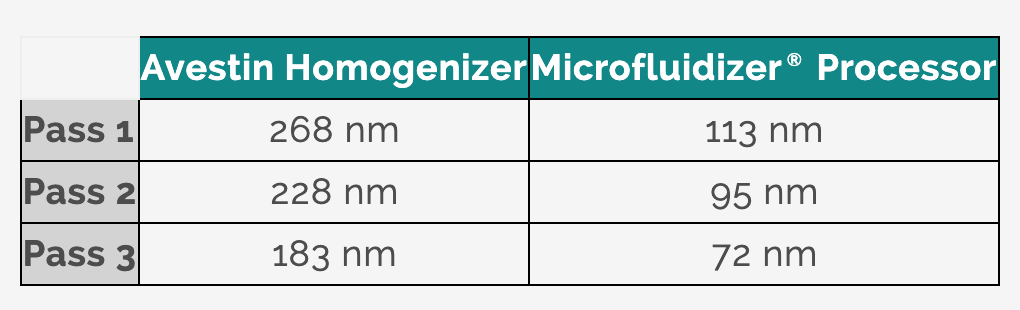

This results in significantly smaller average particle sizes. A test was conducted to compare a Microfluidizer®processor and an Avestin homogenizer in liposome processing. Both pieces of equipment were operated at 30,000 psi. As shown in the chart opposite, the Microfluidizer® processor achieved more than 50% smaller particles at every pass.

Uniform Processing Pressure

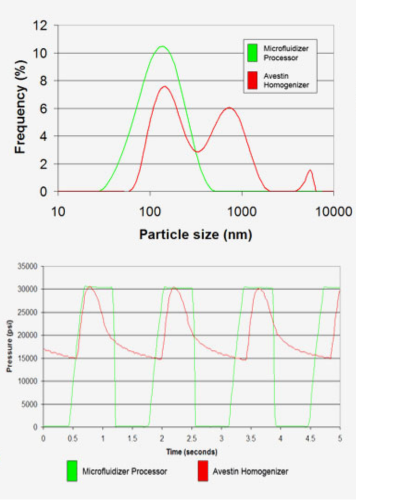

Another key advantage of the Microfluidizer® processor is its ability to produce more uniform output vs. a homogenizer, as demonstrated in the liposome processing results.

Homogenizers operated at peak pressures for mere moments (approximately 7%) of each cycle (see chart below), which leads to wider deviations, less stable products, and the need to run more passes or use higher pressures than should be required — potentially denaturing proteins during cell rupture and adding time, energy and cost to the production process. Conversely, Microfluidizer® technology generates consistent shear in order to produce reliable and repeatable results.

Customers compare Microfluidizer® processors and conventional Homogenizers

Customers who have upgraded to a Microfluidizer® processor routinely report the following observations about conventional homogenizers:

- Due to wide pressure variations, the machine must be monitored and adjusted constantly during operation

- Homogenizers often shut down due to an overdraw of current, even below maximum pressure

- They frequently plug up when attempting to process materials with high solid-load content

- Homogenizers are difficult to prime and the typical workaround is unsafe and damages the machine

- Proper startup requires five minutes, so startup is often bypassed, which shortens the life of machine components