Nov 1, 2023 7:53:22 PM

Microfluidics is celebrating its 40th year and this blog explores & celebrates..

Polymer nanoparticles represent one of the most innovative drug delivery systems due to their ability to deliver a wide variety of drugs and improve efficacy. Initially formulated like emulsions, a very small droplet consisting of a solvent containing both the polymer and drug of choice is formed. Once the solvent is evaporated, the polymer hardens and encapsulates the drug leaving very small, solid particles.

EXPLORE:

Useful in targeted delivery of drug molecules to improve therapeutic efficacy, it is important to be able to control the manufacturing process. Once R&D formulations have been met, repeatable consistent scaleup is essential for larger commercialization volumes.

Our technology achieves reproducible high shear forces to control particle size giving polymer nanoparticles the ability to be terminally sterilized via filtration and controlled release.

Microfluidizer® processors are designed to be simple to use and clean with the option of conforming to cGMP requirements.

Our 40 years of application development and machine engineering provide the experience to help drive your product to market as quickly as possible.

Biodegradable polymer nanoparticles are an innovative drug delivery system, offering a number of benefits:

Microfluidics' scalable and simple to use technology offers an ideal solution for polymer nanoparticle formulation. Let our team of experts guide you through your options.

Factors to be considered in selecting the solvent:

This application note explains some key formulation considerations when developing water-in-oil (W/O) emulsion evaporation processes as well as a step-by-step guide for creating polymer nanoparticles using Microfluidizer® processors.

Processing steps:

Solvent Extraction process:

OR

By working together with your formulation expertise, our engineers find the optimal solution in meeting your product goals. Our experienced process and application engineers accelerate nanomaterials development, improve production efficiency, and train and educate personnel.

With a worldwide reputation and proven track record in creating best-in-class nanoemulsions, our dedicated and talented team has the expertise to help you achieve your target particle size and distribution curve.

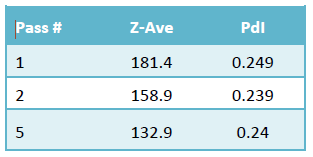

Microfluidizer® technology produces on-target particles. Particle size analysis is often used to evaluate polymer nanoparticles.

Utilizing specific analytical techniques, including dynamic light scattering, optical microscopy, and SEM or TEM, we have found that Microfluidizer® technology is able to reduce polymer droplet size significantly after several passes.

Recommended downloads for manufacturers looking to achieve on-target particle sizes for polymer nanoparticles.