Scalable High-pressure Homogenizing Technology

Of course, achieving success in the lab is valuable only if it can be repeated reliably, regardless of scale.

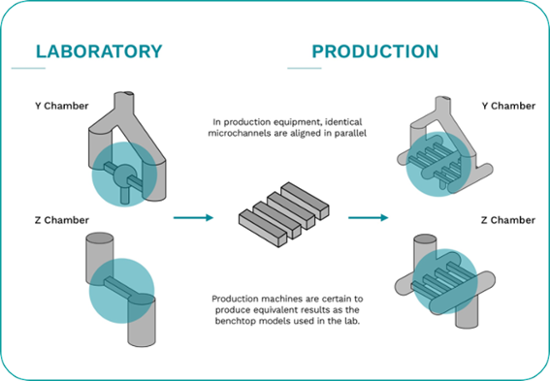

Microfluidizer® technology is further differentiated from other technologies, not only in its ability to replicate results batch-to-batch, but also in its capacity to duplicate results from lab environments to pilot and production volumes.

The process of transferring the results of lab-scale R&D work to the pilot plant and then finally on to production scale is a critical link in the pharmaceutical production chain. Microfluidics combines unrivaled process knowledge with proven reliable technology which enhances pharmaceutical scale up.

The result is a process scale up that delivers:

- increased process reliability

- optimal production rates

- fewer product defects

- efficient pharmaceutical validation

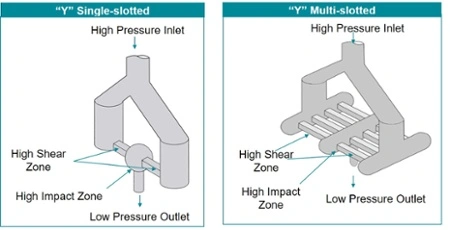

This reliable scale-up is achieved by aligning microchannels in parallel within the Interaction ChamberTM, with a single output reservoir. This ensures that the entire product stream experiences identical shear, resulting in consistent quality no matter the volume — from 1 ml up to thousands of liters per minute.