Microfluidics Technology Lab

Test, Research, Develop and Innovate

The Microfluidics' Technology Centre, located outside of Boston, Massachusetts (USA), is a state-of-the-art facility providing our customers with leading-edge technology and equipment to support their testing and needs.

About the Lab

Microfluidics’ laboratory application experts work with global customers to understand their specific application needs, in conjunction with our technology, to advise on which processing conditions will yield the best results for their specific applications.

Our team of experts are recognized as global leaders in nanotechnology solutions and lecture throughout the world on their application knowledge of complex application case studies. Our application laboratory team works with a wide range of customers to solve their specific nanoparticle challenges. Our team of application engineers and subject matter experts have an in-depth understanding of various applications including lipid nanoparticles, nanoemulsions, cell disruption and particle size reduction.

For a live demonstration of their specific formulation, our customers are welcome to come on-site to ask questions and engage our team to best understand the goals and challenges of their particular needs. If visiting our site is not possible, our team will work closely with each customer as to best achieve their objectives.

Key Features

Whether a customer or a potential customer, our Microfluidics team provides attention and education to each challenge. All lab challenges are asked a full range of questions to best understand each problem and ensure goals are aligned. Our team provides a detailed report of all test results and can be trusted to adhere to a strict confidentiality agreement:

Our Microfluidics Technology lab offers the following services:

- Supporting the development of customers' new products using feasibility tests.

- Identifying improvements to existing manufacturing processes and/or established products.

- Proof of concept for process scaling with a wide range of equipment, from lab-scale to pilot-scale and production-scale.

- Ability to trial equipment before purchasing.

The Microfluidics Lab offers three kinds of tests to best serve our customers and potential customers.

Proof-of-Concept Test

Designed to educate our customers on the capabilities of a Microfluidizer® processor.

Potential customers provide a formulation to be processed under varying conditions.

By modifying the type of Interaction Chamber™, processing pressure, and number of passes, the processing results are impacted. Measuring particle size as the base of comparison, these changes provide an opportunity to showcase the Microfluidizer® technology’s superior results.

As the leader in high shear fluid technology, this test showcases Microfluidics' advantages to individuals unfamiliar with processing innovation.

Process Optimization Test

Designed to attain a customer’s specific result based on their particular project.

Our lab application team work diligently with customers to modify formulations to achieve specific objectives and results for a customer’s nano technology challenge.

By varying the processing conditions, exact results can be achieved.

Our subject matter experts and application engineers partner with our customers to help meet their nanotechnology goals for their particular need. Our team of experts are trained on both application and equipment to evaluate and modify results until our customer is successful in their end target.

Scale-up Test

Designed to prove Microfluidics' key scalability benefit on pilot and production scale volumes.

In performing this test, our lab team splits a large batch of material provided by our customer. Some material is tested on either a lab or pilot scale Microfluidizer® processor and the remainder, of the material, is tested on our production scale Microfluidizer® processor.

This test allows our application team to prove that by processing under the same conditions (such as the Interaction Chamber™, pressure and number of passes) the exact results will be achieved whether it’s processed on a lab scale, pilot or production scale model.

What Machines Can I Test With?

High shear fluid processors for creating nanoemulsions, uniform particle size reduction, deagglomeration and cell disruption.

LM10

The LM10 Microfluidizer® High Shear Fluid Homogenizer is a digitally controlled benchtop model used for small sample material processing. The LM10 processor consistently achieves repeatable results and saves on development time in pilot and production scale-up.

LM20

As a benchtop processor, this digitally controlled LM20 excels at efficiently converting high fluid pressures to intense shear forces. This lab scale model is a powerful tool in the research and development field. This dynamic processor is capable of achieving unmatched particle size reductions at lower process pressure.

M110P

Used by top pharmaceutical and biotech industries, this impressive benchtop high shear processor is easy to use across many applications. Delivering repeatable results and guaranteed to scale-up to pilot and production volumes, this processor is designed for cGMP capability abilities.

LV1

The LV1 benchtop processor brings Microfluidizer® quality nanotechnology to the milliliter scale. The LV1 is the ideal processor for high value samples which require a minimal amount of product for machine operation while still maximizing recovery.

M110EH

As a versatile processor, the M110EH is the workhorse of the Microfluidics product line. This pilot scale processor can achieve optimal results with small volumes or achieve repeatable results as a small production scale. The M110EH achieves superior results for many applications and has the option of cGMP capabilities.

M815

Due to the revolutionary Interaction Chamber™ technology, the M815 high shear processor is capable of providing repeatable results on both pilot and small production scale volumes. As a self-contained unit, the M815 is easy to both operate and maintain.

M7250

As a production scale processor, the M7250 can efficiently achieve repeatable results for manufacturing volumes and global distribution. Used by top, global pharmaceutical companies, the M7250 is a proven machine to replicate research and development results into distribution channels.

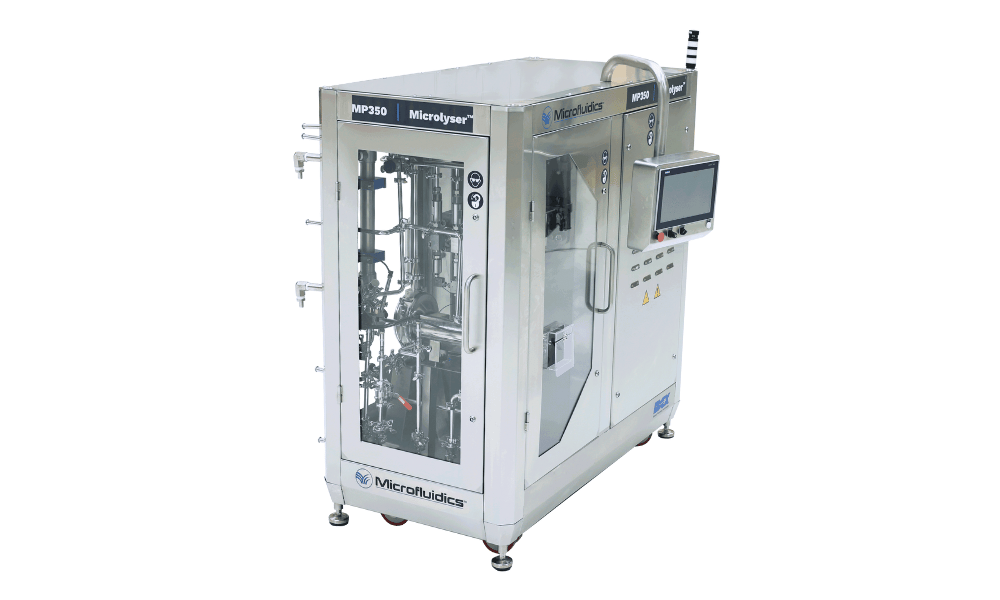

MP350

An innovation in maximizing high yields in cell disruption on the production scale, The MP350 Microlyser™ incorporates Microfluidics' proprietary Interaction Chamber™ technology, with a unique sanitary, electric pumping system. Designed specifically for biotech applications and engineered with full cGMP compliance in mind, this production scale machine ensures repeatable results batch-to-batch.