We recently caught up with Chris Jaquin, a Syracuse University chemical engineering graduate, who has spent five years as an applications engineer at Microfluidics - a global supplier of Microfluidizer® high shear fluid processors.

Hello Chris, tell us about your current role and key duties at Microfluidics.

I work with customers in the lab to figure out the best way to handle their specific products on our Microfluidizer® processors. As an application engineer, my main responsibility is to have a solid understanding of the various applications which we see, handle and process in the lab. The most common applications I work with are nanoemulsions, cell disruption and particle size reduction although I do have experience working with additional applications. I work with our customers to understand their specific application needs, then in conjunction with my knowledge of our technology, I am able to advise on which processing conditions on the Microfluidizer® processor will yield the best results for their specific applications. Some of the work I do with customers is just discussing their applications and their processing goals, but sometimes customers may bring materials into the lab so we can process it and analyze it more fully. They often look to us to provide suggestions on how they could process their material in the future.

.webp?width=400&height=296&name=Microfluidics_difference.PNG%20(1).webp)

What tests are performed in the Microfluidics lab?

Within our lab, we offer three kinds of testing.

The 1st and most common test is the proof of concept testing. This test is designed for a customer who has never used our technology and wants an understanding of the capabilities of a Microfluidizer® processor. Typically, a customer brings us a formulation, which we process, whilst we vary the processing conditions. These processing conditions include the type of Interaction Chamber™ (which allows constant shear forces so all material to be processed under the same processing pressure), the processing pressure, and the number of passes. We vary these three parameters to display how changing a specific parameter may affect the processing results. We usually study and compare particle size as the main way to characterize the samples. The goal of this test is to show trends to the customer so they can make a more informed purchasing decision.

The 2nd type of test that we run in our lab is our process optimization test. This test differs from the proof of concept test because we're not trying to display the capabilities of the Microfluidizer® processor but instead we are trying to attain the customer’s specific desired result. This is a more involved test than showing the trends that changing a processing condition might result in it. It requires us to vary the processing conditions to get exact results. Although we're not formulation experts, we have a collective of 40 years of experience running these tests so we are confident that we can work with customers to slightly modify formulations in order to achieve the desired results and achieve the customer’s goals, if necessary.

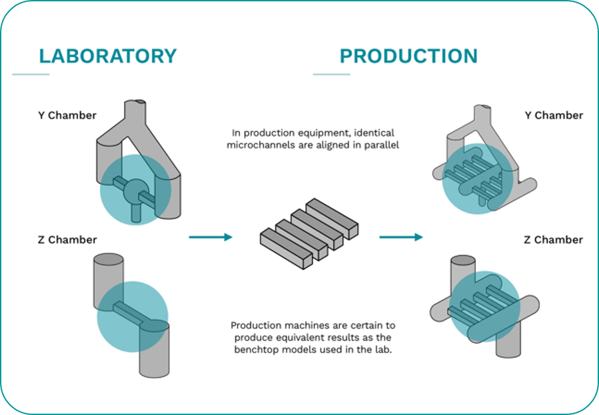

The 3rd test that we run in our lab is the scale-up test. One of the major benefits of Microfluidizer® technology is that it is completely scalable. Customers want us to prove this scalability. For this test we split a large batch of material, with some being tested on either a lab or pilot scale Microfluidizer® processor and the remainder is tested on our production scale Microfluidizer® processor. This allows us to prove that as long as material is processed under the same conditions (meaning with the same Interaction Chamber™, same pressure and same number of passes) the exact results will be achieved whether it’s processed on a lab scale or production scale model.

Can you give us an example of how we solve Customers' Problems?

As an example, there are 3 major types of cell lines that we work with-mammalian, bacterial and yeast cells. In cell disruption, our Microfluidizer® processors are very efficient at lysing cells. However, depending on the particular cell line, cell concentration, and cell type, we need to apply different levels of shear. By working with customers and trying out a variety of different processing conditions we’ve been able to establish the optimal range of conditions that we need for each of these different cell types.

With mammalian cells, we’ve ascertained that they require the lowest amount of shear of the common cell types that we see processed on our technology. We have established this through our experience as we run tests by calibrating Interaction Chamber™ size and geometry, processing pressure and number of passes. We are confident that we can achieve a high level of lysis and since the product passes through a cooling mechanism, we’re confident we aren’t denaturing or damaging any of the intracellular components that we’re looking to collect. The benefit of our technology is that we have the ideal levels of shear.

Our technology provides enough shear force to lyse the cells, but not too much shear as to damage other intracellular components. By having an efficient cooling system immediately downstream from the Interaction Chamber™, we are also confident that the temperature increase experienced by the sample passing through the Interaction Chamber™ will be extremely brief and will not damage any intracellular components. By adjusting Interaction Chamber™ size and geometry, processing pressure, and number of passes, we can also process bacterial and yeast cells. Based on our prior experience, we are confident that even when we’re providing higher levels of shear (which can result in higher levels of energy dissipation and a more significant brief temperature increase) the integrity of the intracellular components will be maintained due to the cooling immediately after the Interaction Chamber™.

Any concerns that you are seeing with our customers which we can help with?

We have many customers in the pharmaceutical industry who are producing nanoemulsions. For these nanoemulsions, everything must be sterile. However, processing in a completely sterile environment can be very, very expensive. So, some of these customers may choose to sterile filter their products rather than process under completely sterile conditions. Sterile filtration is done through membranes that have a mesh where the average pore size is approximately .2 microns or 200 nanometers. Thus, our customers processing these emulsions need their droplet size to be smaller than 0.2 micron.

We have been able to prove that our technology is capable of creating an entire particle size distribution below this size as opposed to creating an average size below that .2 Micron. When you look at particle size in a batch, it is a distribution of particle sizes so if your average size is 150 nanometers, there will be a population of particles smaller and another population of particles bigger. The width of the distribution curve matters. Even if the average size is below the 200 nanometer mark, if there is a significant population that’s over 200 nanometers, the filter is going to clog and it’s a less efficient filtration process. Therefore, we focus on creating emulsions that are not only small but also have a very tight particle size distribution or PDI (polydispersity index), which means the material is suitable for the sterile filtration process.

Advice you would give perspective customers looking for high shear processors.

When working with high shear processors there are three major components you want to look for: You obviously want it to be efficient. You want it to be repeatable and you want it to be scalable. Microfluidizer® technology is able to accomplish all three.

When it comes to efficiency, the aim is to hit your target size as quickly as possible. Microfluidizer® processor incorporates a fixed geometry Interaction Chamber™ which allows a constant pressure profile within the processing module. This Interaction Chamber™ allows us to have constant shear forces that enable all material to be processed under the set processing pressure, so all product sees the same high levels of shear. Therefore, the majority of material is treated at the same conditions and will be able to reduce either the particle size or the droplet size more efficiently because all of the material is being processed under the same conditions.

This efficiency also helps with repeatability, as well, because there’s a lack of variability in the process pressure and therefore a lack of variability in the shear rate. When processing with a Microfluidizer® processor from one batch to another, there is a guarantee that processing conditions (the Interaction Chamber™, the process pressure, number of passes along with the premixing conditions) are the same. We have a high confidence level that you’ll be able to achieve the same results from one batch to the next because of the nature of our technology due to our fixed geometry Interaction Chamber™.

Therefore, when we scale up, we align microchannels in parallel within the Interaction Chambers™ which allows for higher throughput as material is still seeing the exact same processing conditions. This allows us to guarantee scalability which is clearly very important. If you’re working on a lab-scale model with the intention to eventually create a commercial product you want to be able to ensure that what you’re doing on the lab scale will be replicated on the production scale. Otherwise, you will have to completely re-optimize your product for a new piece of equipment, which is not ideal when you’re looking to go to production quickly.

Why would our customers choose Microfluidics?

Three major components that put us ahead of our competition are as previously stated-efficiency, repeatability and scalability of the process. But another important component is that we are a very customer-obsessed company. It is a responsibility for all of us to be in constant communication with our customers.

On the application side, for me specifically, it’s understanding the customer’s application and how we may be able to best produce the product on a Microfluidizer® processor. We provide suggestions pertaining to everything from the processing conditions, occasionally to the formulation itself, to even the surrounding processes such as the premix.

Our engineering department is skilled at figuring out which options our customers need for their machine and identifying which utilities they need to have installed.

Once a customer has the machine installed, our aftermarket team supports them and ensures they quickly get back to customers with the shortest lead time possible.

Microfluidics really stands out from its competition because we’re always focused on customers, we’re always speaking with our customers and we’re really doing our best to serve our customers in any way possible.

If you would like to find out more about the Microfluidics approach, then please contact us.

Posted by

Matt Baumber