PRODUCTS

Biopharmaceutical Manufacturing Equipment (cGMP)

Microfluidizer® Processors for Biopharmaceutical Applications

Microfluidics offers a complete range of Microfluidizer® processors. Designed specifically for pharmaceutical and biotech applications, and engineered with full cGMP compliance in mind, our precision-designed/manufactured machines readily achieve diverse applications — such as nanoemulsions, suspensions, cell disruption and liposomes — efficiently, predictably, and reliably.

At the heart of our success — and yours — is our unique fixed-geometry Interaction Chamber™. Only Microfluidizer® pharmaceutical homogenizers feature this crucial component, which ensures that every milliliter of your product experiences virtually identical, intense shear forces under extreme, user-controlled pressure. This allows you to achieve tightly controlled, highly predictable homogenization results. (Often within one or two passes.) Our machines yield remarkably tight particle size distributions and smaller particle sizes than are typically achieved using other pharmaceutical machinery manufacturers’ equipment.

Inherent continuity and compatibility are built into every machine and equipment series, so exceptionally smooth process scaleup is guaranteed. Whether you are perfecting the mixing process to achieve optimal product parameters or scaling up to pilot or production-scale runs, each batch generated using Microfluidizer® technology in pharmaceutical processing equipment matches the last.

Lab Scale

M110P

Good things come in small packages. In the pharmaceutical industry, all good things start in the laboratory. The journey from concept to R&D, to pilot runs, through clinical trials and the FDA approval process, to the final manufacturing phase, begins with benchtop investigation. This small, “plug-and-play” benchtop cGMP-ready, continuous high shear fluid processor may not take much space, but it’s more than capable of handling challenging tasks on a small batch scale. Achieve stable nanoemulsions, stable nanodispersions, cell rupture/cell disruptions, deagglomeration, microencapsulation and more, with processing pressures up to 30,000 psi. Then, scale up seamlessly by switching to one of our larger, companion homogenizer machines.

Pilot Scale

M110EH

Still agreeably modest in its footprint, the Pilot Scale M110EH allows you to scale up from R&D to pilot runs with seamless scalability. Achieve uniform particle sizes, stable nanoemulsions and nanodispersions, and effective nanoencapsulation of active pharmaceutical ingredients (APIs). Microfluidics machines excel at achieving efficient cell disruptions, including notoriously challenging cell types, such as yeast and plant cells.

Production Scale

M700

Progress from R&D, to pilot runs, to the production of products suitable for clinical testing — and then on to full production runs with the Microfluidizer® processor family of highly compatible biopharmaceutical manufacturing machines. Our M700 processors enable you to replicate operating conditions — and results — from batch-to batch, as you scale up production. Available in basic, enhanced or aseptic models

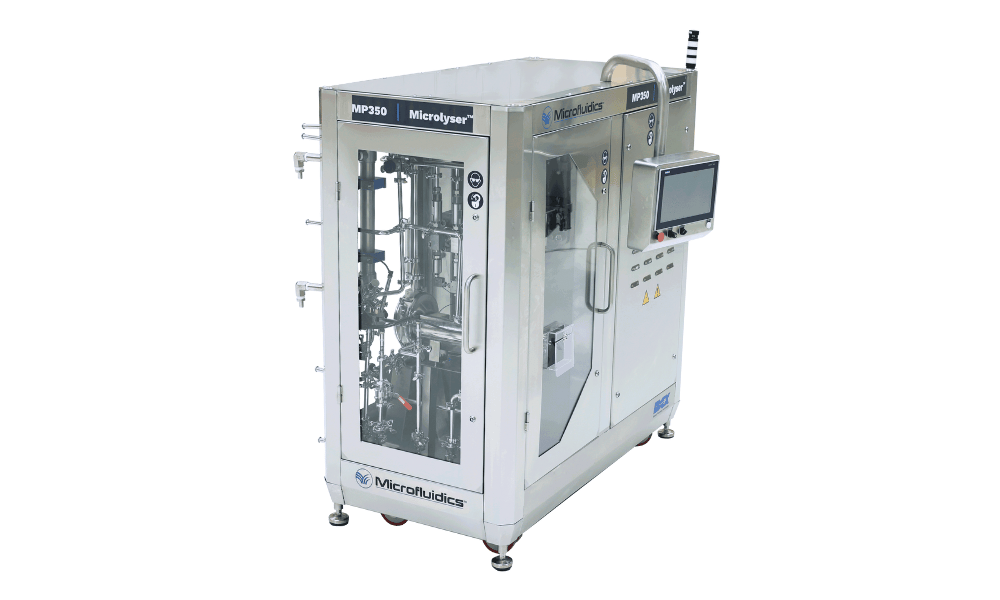

MP350

Designed with full cGMP compliance in mind, the MP350 Microlyser™ processor maximizes high yields in cell disruption on the larger production scale. By utilizing a patented electric pumping system with Microfluidics’ Interaction Chamber™ technology, material undergoes identical conditions and guarantees repeatable results batch-to-batch at production volumes. This innovative hybrid approach is an ideal cell disruption solution for a variety of cell types -from E. coli to difficult yeast cells.

cGMP Manufacturing

Our biopharma equipment and other machines are used in more biopharma productions globally — including in the production of many FDA-approved drugs — than any of our competitors’ products. In fact, we are the world’s premier provider of biotech and pharmaceutical high shear processing equipment.

Microfluidics is a best-in-class manufacturer. We have more than 15 years of experience with cGMP requirements for pharmaceutical applications. Count on our in-depth professional knowledge, expert support, and high-quality biopharmaceutical manufacturing equipment for the most effective submicron particle size reduction and optimal yield for all your biotech and pharmaceutical productions.